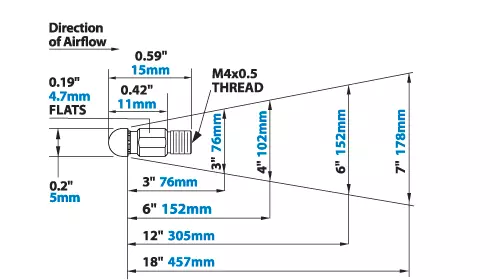

Back Blow Air Nozzle

EXAIR's Back Blow Air Nozzles are engineered to clean inside of pipe, tube, hose or channel. An array of holes provide a forceful 360 degree air flow to clear out coolant, chips or debris created from machining processes. This nozzle prevents blowing chips further into a pipe or out the end, which could create a safety hazard. Since air flow is directed back toward the operator personal protective equipment is recommended. They deliver high performance suitable for a wide range of diameters from 1/4" (6.3mm) up to 16" (406mm)!